Chemical filter is widely used in petroleum and chemical industry. Solid impurity particles contained in gas phase and liquid phase materials are separated by Filter Elements to prevent equipment and pipe fittings from being damaged or blocked after entering the device, so as to ensure the normal and stable operation of production equipment. Therefore, how to design and use the filter correctly, safely, economically and reasonably is very important.

Chemical filter is widely used in the separation of solid impurity particles in gas phase and liquid phase material in petroleum and chemical industry, and the recovery and reuse of adsorbent and catalyst. By filtering the solid impurities contained in the materials, the equipment and pipe fittings damage or blockage caused by the solid impurities particles entering the device are prevented, the production medium meets the process design requirements and the normal and stable operation of the production device, and the safety and use cycle of the relevant equipment of the production device are protected.

Firstly, the type of filter is selected according to the property of medium, temperature and pressure;

2. The pressure level of the filter is generally higher than the medium pressure in the pipeline;

3 for the medium with high freezing point, high viscosity and more suspended solids, horizontal backwash filter should be selected;

4. Basket filter is generally used for medium with high solid impurity content and high viscosity;

5 for flammable, explosive and toxic media, the filter with butt welding connection should be used. When the pipe diameter is less than Dn40, the filter connected by socket welding should be used.

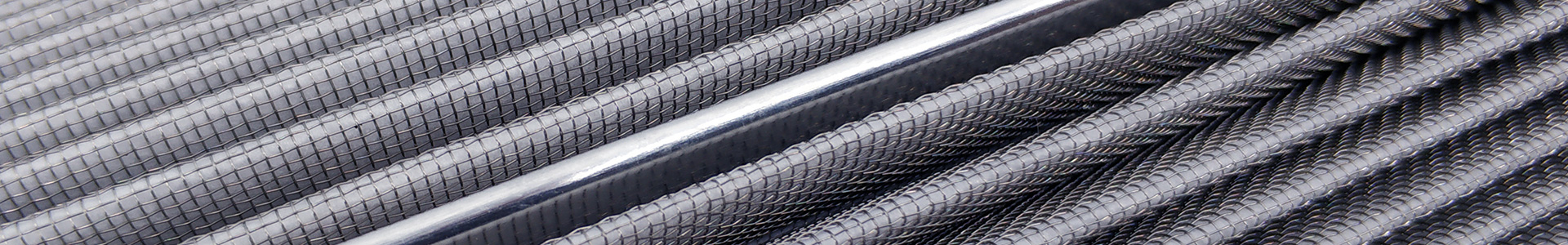

The difference between equipment type filter and pipeline type filter is mainly the difference of filter elements, filtering accuracy, equipment size, equipment design and manufacturing requirements. Although the pipeline filter has the advantages of simple structure, low manufacturing cost and small equipment size, it has the problems of low filtering accuracy, small filtering area and low structural strength of filter basket.

The equipment type filter, due to its large filtering area and settling time, high filtering accuracy and structural strength, long service life and online washing and replacement of filter element, can effectively solve the related problems of the above pipeline type filter, and is more suitable for the long-term and stable operation of the device.

In the application of chemical industry, the appropriate chemical filter can be selected and used safely, economically and reasonably according to the application situation, the physical properties of medium and the production process requirements.